Return Pin: Essential Component for Mold Efficiency

Return pins are one of the most critical components in the plastic injection molding process. These small but essential parts play a significant role in ensuring smooth, efficient, and precise mold operations. At FENG ZHOU INDUSTRIAL CO., LTD., we specialize in high-quality return pins that help maintain the productivity and accuracy of manufacturing processes.

What is a Return Pin?

A return pin is a critical component in the mold system that facilitates the return of the mold to its original position after the ejection process is completed. During injection molding, once the molded part is ejected, the return pin ensures that the mold halves reset to their correct position, preparing the system for the next molding cycle.

Functions of a Return Pin in Molding

The role of a return pin is crucial to the overall efficiency and precision of the molding process. Here are the key functions it serves:

1. Facilitates Mold Reset

Once the ejector pins push out the molded part, the return pins help guide the mold back to its original closed position. This ensures that the mold is ready for the next cycle without any manual intervention, maintaining efficient production flow.

2. Enhances Cycle Efficiency

Return pins are instrumental in reducing cycle times. By ensuring quick and accurate mold resetting, they minimize the downtime between cycles, thus increasing the overall efficiency of the injection molding process.

3. Ensures Mold Alignment

Precise alignment of mold halves is critical for maintaining the quality of molded parts. Return pins play a significant role in ensuring that the mold closes correctly, maintaining the alignment needed for accurate part dimensions.

Material Considerations for Return Pins

The materials used to manufacture return pins directly affect their performance and longevity. Common materials include:

- Hardened Steel: Known for its high strength and wear resistance, hardened steel is ideal for applications where return pins are subject to repeated cycles and high pressures.

- Stainless Steel: Offering corrosion resistance and durability, stainless steel return pins are suitable for environments exposed to moisture or chemicals.

- Alloys: In some cases, specially formulated alloys are used to enhance specific performance characteristics, such as wear resistance or heat tolerance.

Selecting the right material ensures the return pin can handle the stress of high-volume production without frequent wear or failure.

Benefits of High-Quality Return Pins

1. Improved Durability

Return pins must endure thousands of cycles in high-pressure environments. By using high-quality materials and precision manufacturing, return pins offer excellent durability, ensuring that they last longer and reduce the need for frequent replacement.

2. Increased Efficiency

High-quality return pins contribute to the overall efficiency of the mold by reducing the cycle time and ensuring that the mold resets accurately. This minimizes the risk of defects and downtime, resulting in increased productivity.

3. Precise Performance

Accuracy is key in injection molding, and return pins ensure that each mold cycle starts with perfect alignment. This helps maintain the quality of the molded parts and reduces the likelihood of misaligned molds causing part defects.

Why Choose FENG ZHOU INDUSTRIAL CO., LTD. for Return Pins?

At FENG ZHOU INDUSTRIAL CO., LTD., we understand the importance of reliable and durable return pins in the injection molding process. Our return pins are manufactured using premium materials and state-of-the-art engineering techniques to ensure they meet the highest industry standards. With a focus on precision and durability, our return pins are designed to boost the performance and longevity of your molds.

Our Key Advantages:

- High-Quality Materials: We use only top-grade materials like hardened steel and stainless steel for superior wear resistance.

- Precision Manufacturing: Our return pins are crafted with exacting tolerances to ensure precise alignment and smooth operation.

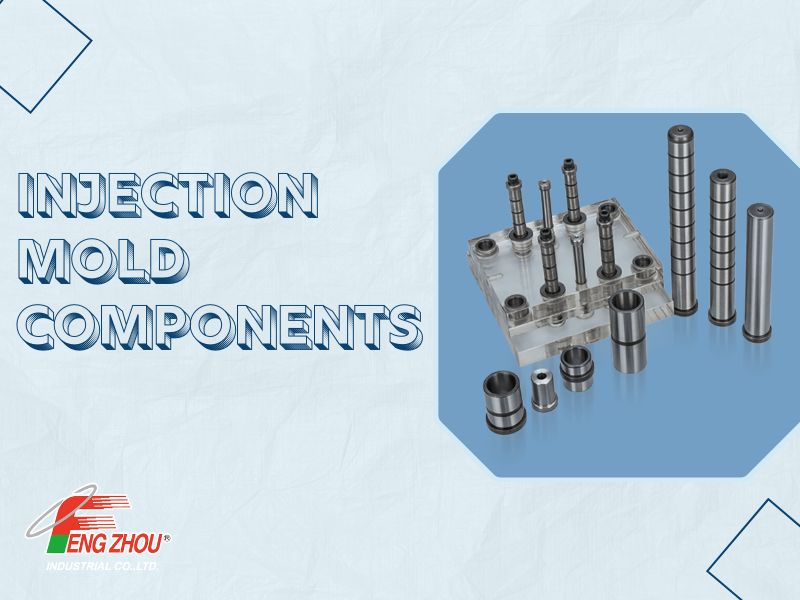

- Comprehensive Solutions: We offer a range of mold components that work together seamlessly to enhance your manufacturing processes.

Conclusion

Return pins are an essential part of any efficient mold operation, playing a key role in ensuring that molds reset accurately and quickly after the ejection of parts. High-quality return pins can significantly improve the productivity, precision, and durability of your injection molding processes.

At FENG ZHOU INDUSTRIAL CO., LTD., we offer premium return pins that are designed to meet the demands of high-volume, precision manufacturing. For more information about our return pins and other mold components, contact us today. We're committed to delivering solutions that enhance your productivity and meet your precision engineering needs.

LASTEST TECHNOLOGY