Guide Pin: The Key to Precision and Efficiency in Manufacturing

In precision manufacturing, accurate alignment is crucial to achieving consistent, high-quality results. One essential component that ensures proper alignment and smooth operation in various industries, especially injection molding, is the Guide Pin. At FENG ZHOU INDUSTRIAL CO., LTD., we produce high-quality guide pins designed to optimize manufacturing efficiency and product quality.

This article explores what guide pins are, their functions, benefits, and why they are indispensable in precision manufacturing.

What is a Guide Pin?

A guide pin is a cylindrical component used to align and guide moving parts, such as mold halves in injection molding or tooling components in machine operations. Paired with guide bushings, guide pins ensure that parts move smoothly and stay precisely aligned during repetitive operations.

Guide pins are typically made from durable materials such as hardened steel, stainless steel, or specialized alloys to withstand high pressures and continuous use.

Key Functions of a Guide Pin

1. Accurate Alignment

Guide pins help maintain the precise alignment of mold halves or tooling parts during operations. Accurate alignment is critical in ensuring that the finished product meets strict quality standards and specifications.

2. Smooth Movement

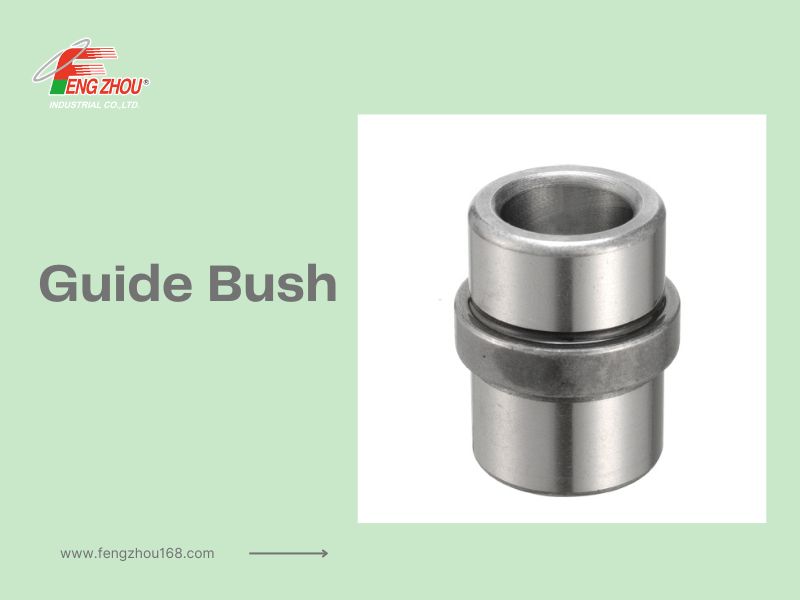

Paired with guide bushings, guide pins facilitate smooth, controlled movement between components. This reduces friction, wear, and the likelihood of misalignment, ensuring consistent performance.

3. Stability During Operations

Guide pins stabilize the movement of parts under high-pressure conditions, preventing unnecessary shifting or vibration. This stability is essential for maintaining product consistency and minimizing defects.

4. Repeatable Precision

In high-volume manufacturing, guide pins enable repeatable precision across thousands of cycles. Their consistent performance reduces variability and helps maintain high production yields.

Benefits of Using Guide Pins in Manufacturing

1. Enhanced Product Quality

Guide pins ensure accurate alignment, resulting in products with consistent dimensions and fewer defects. This precision helps manufacturers meet quality control standards and reduce waste.

2. Reduced Friction and Wear

High-quality guide pins, often paired with oil-groove guide bushings, minimize friction between moving parts. This reduces wear on the mold or machinery, extending the life of the components and decreasing maintenance costs.

3. Increased Efficiency

By maintaining precise alignment and smooth movement, guide pins reduce cycle times and downtime caused by misalignments or component failures. This leads to higher productivity and efficiency in manufacturing processes.

4. Durability and Longevity

Made from hardened steel or stainless steel, guide pins are highly durable and capable of withstanding repetitive use under high-pressure conditions. Their long service life helps reduce the frequency of replacements.

5. Versatility Across Industries

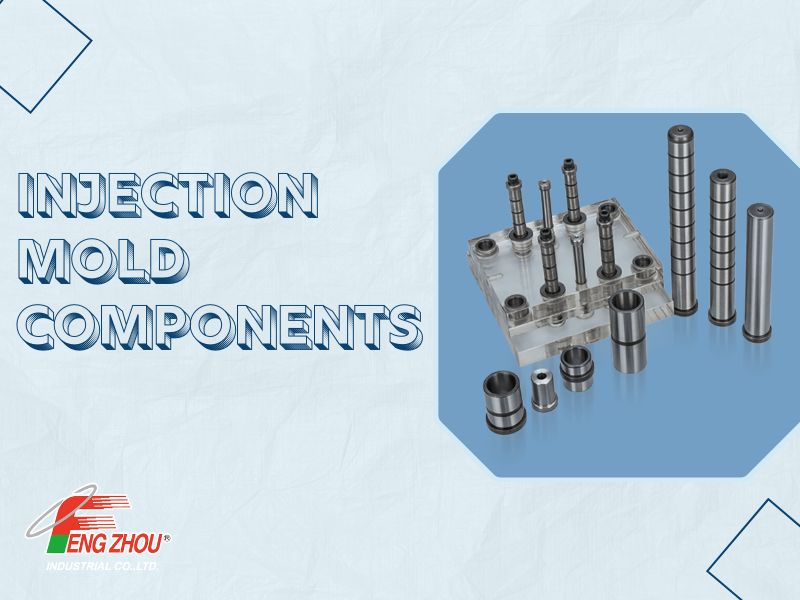

Guide pins are used in various industries, including:

- Injection Molding: Ensuring accurate alignment of mold halves.

- Automotive: Supporting the production of high-precision parts.

- Aerospace: Facilitating the manufacturing of components requiring tight tolerances.

- Electronics: Assisting in the creation of intricate, small-scale components.

Why Material Quality Matters for Guide Pins

The performance of guide pins heavily relies on the quality of the materials used. Common materials include:

- Hardened Steel: Provides excellent wear resistance and durability, suitable for high-pressure applications.

- Stainless Steel: Offers corrosion resistance, ideal for environments exposed to moisture or chemicals.

- Alloys: Specialized alloys can provide additional properties, such as enhanced strength or heat resistance.

Choosing high-quality materials ensures guide pins deliver reliable performance and extended service life.

Why Choose FENG ZHOU INDUSTRIAL CO., LTD. for Guide Pins?

At FENG ZHOU INDUSTRIAL CO., LTD., we specialize in manufacturing precision-engineered guide pins that meet the highest industry standards. Our guide pins are designed to optimize alignment, reduce friction, and enhance the efficiency of your manufacturing processes.

Key Advantages of Our Guide Pins:

- Premium Materials: Made from hardened steel, stainless steel, or specialized alloys for durability and wear resistance.

- Precision Tolerances: Engineered with tight tolerances to ensure accurate alignment and smooth movement.

- Reliable Performance: Consistent quality that reduces downtime and maintenance costs.

- Versatile Applications: Suitable for a wide range of industries, including injection molding, automotive, and aerospace.

Conclusion

Guide pins are essential components in precision manufacturing, ensuring accurate alignment, smooth movement, and stable operations. By investing in high-quality guide pins from FENG ZHOU INDUSTRIAL CO., LTD., manufacturers can enhance product quality, increase efficiency, and reduce maintenance costs.

To learn more about our guide pins and how they can optimize your manufacturing processes, contact us today. We are committed to delivering reliable, high-performance solutions that meet your precision engineering needs.

LASTEST TECHNOLOGY