How Injection Mold Components Enhance Efficiency in Manufacturing

Injection mold components are the backbone of precision manufacturing, ensuring that processes run smoothly, efficiently, and reliably. These components play a crucial role in the functionality and productivity of injection molding systems, which are widely used in industries such as automotive, aerospace, electronics, and consumer goods. At FENG ZHOU INDUSTRIAL CO., LTD., we specialize in producing high-quality injection mold components designed to optimize manufacturing efficiency.

In this article, we will explore how injection mold components contribute to improved productivity, precision, and cost-effectiveness in modern manufacturing processes.

What Are Injection Mold Components?

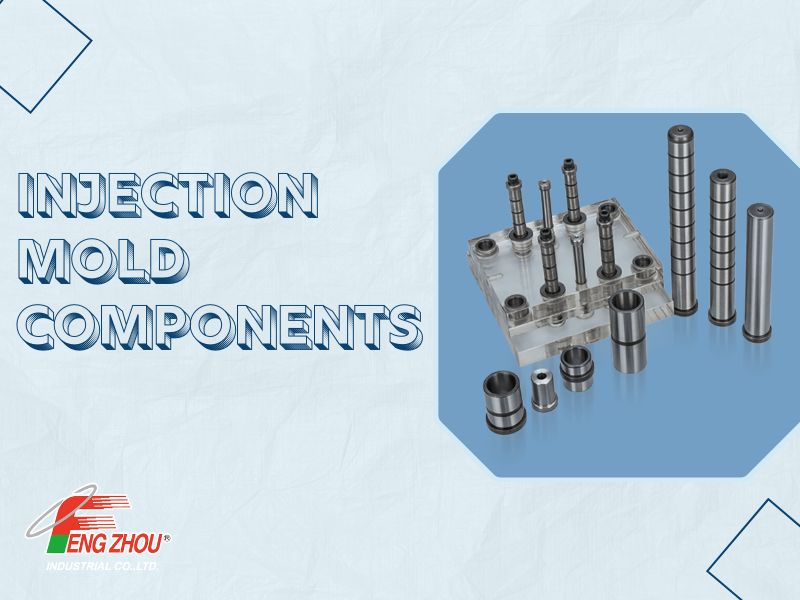

Injection mold components are the individual parts that make up the injection mold system. They work together to shape molten plastic into precise, high-quality parts. These components include:

- Guide Pins and Guide Bushings: For accurate alignment of mold halves.

- Ejector Pins: For smoothly ejecting finished products from the mold cavity.

- Sprue Bushings: To direct molten plastic into the mold cavity.

- Return Pins: To reset the mold to its original position after ejection.

- Core Pins: To create internal features in molded parts.

Each component is meticulously engineered to perform a specific function, and together they form the foundation of a well-functioning mold system.

Key Ways Injection Mold Components Enhance Efficiency

1. Precise Alignment for Reduced Defects

Guide pins and guide bushings ensure that mold halves align perfectly during operation. This alignment is critical for maintaining consistent part dimensions and preventing defects such as warping or uneven surfaces. By reducing errors, manufacturers can achieve higher production yields and minimize material waste.

2. Smooth Ejection for Faster Cycles

Ejector pins are designed to smoothly remove finished parts from the mold without causing damage. High-quality ejector pins reduce the risk of delays caused by stuck parts or product deformation, enabling faster cycle times and increased throughput.

3. Optimized Material Flow

Sprue bushings direct molten plastic into the mold cavity with precision. Their design minimizes material waste and ensures uniform distribution, which is vital for creating high-quality products. By optimizing material flow, manufacturers can reduce costs and improve overall efficiency.

4. Durability for Consistent Performance

Injection mold components are made from durable materials like hardened steel, stainless steel, and wear-resistant alloys. These materials ensure that components withstand the stress of high-volume production, maintaining consistent performance over time. Durability translates to less downtime for repairs and replacements, keeping production lines running smoothly.

5. Improved Cycle Efficiency

Return pins and core pins streamline the mold’s operation by facilitating smooth transitions between cycles. These components enable the mold to reset quickly and accurately, reducing downtime and maximizing productivity.

The Importance of High-Quality Components

Using high-quality injection mold components is essential for maximizing efficiency and minimizing operational costs. Poorly designed or low-quality components can lead to misalignments, frequent breakdowns, and inconsistent product quality, all of which can disrupt production and increase expenses.

At FENG ZHOU INDUSTRIAL CO., LTD., our injection mold components are engineered to meet the highest standards of precision and durability. Each component is rigorously tested to ensure it performs reliably under demanding conditions, helping manufacturers achieve their productivity goals.

Applications of Injection Mold Components

Injection mold components are used in a wide range of industries, including:

- Automotive: For producing intricate parts such as dashboards, bumpers, and interior components.

- Aerospace: For manufacturing lightweight, high-strength components used in aircraft and spacecraft.

- Electronics: For creating precise plastic parts in devices like smartphones and laptops.

- Consumer Goods: For molding products such as household items, toys, and packaging.

The versatility and reliability of these components make them indispensable in high-precision manufacturing environments.

Why Choose FENG ZHOU INDUSTRIAL CO., LTD. for Injection Mold Components?

At FENG ZHOU INDUSTRIAL CO., LTD., we pride ourselves on providing injection mold components that enhance the efficiency and performance of your manufacturing processes. Our products are crafted from premium materials and designed with precision to meet the diverse needs of our customers.

Benefits of Our Injection Mold Components:

- High-Quality Materials: Constructed from hardened steel, stainless steel, and alloys for durability and wear resistance.

- Precision Engineering: Ensures accurate alignment, smooth operation, and consistent product quality.

- Wide Range of Options: We offer a comprehensive selection of components for various applications.

- Reliability: Built to withstand the demands of high-volume production.

Conclusion

Injection mold components are essential for maintaining efficiency, precision, and reliability in manufacturing. From ensuring accurate alignment to reducing cycle times, these components play a vital role in optimizing production processes and delivering high-quality results. By choosing high-quality components from FENG ZHOU INDUSTRIAL CO., LTD., manufacturers can achieve greater productivity, minimize downtime, and reduce costs.

For more information about our injection mold components and how they can enhance your operations, contact us today. We are committed to providing solutions that meet the highest standards of precision and quality.

LASTEST TECHNOLOGY