Plastic Mold Components: Essential Parts Explained

In the field of precision manufacturing, Plastic Mold Components play a critical role in ensuring the efficiency and quality of the production process. At FENG ZHOU INDUSTRIAL CO., LTD., we specialize in providing high-quality plastic mold components that meet the stringent demands of various industries. This article will delve into the essential plastic mold components, their functions, and why they are indispensable in precision manufacturing.

Key Takeaways

- Core Components: Plastic mold components are essential for maintaining the accuracy and consistency of plastic manufacturing processes.

- Material Selection: The choice of materials for plastic mold components significantly affects their performance and longevity.

- Precision Engineering: High-quality mold components enhance the efficiency, durability, and overall quality of the manufacturing process.

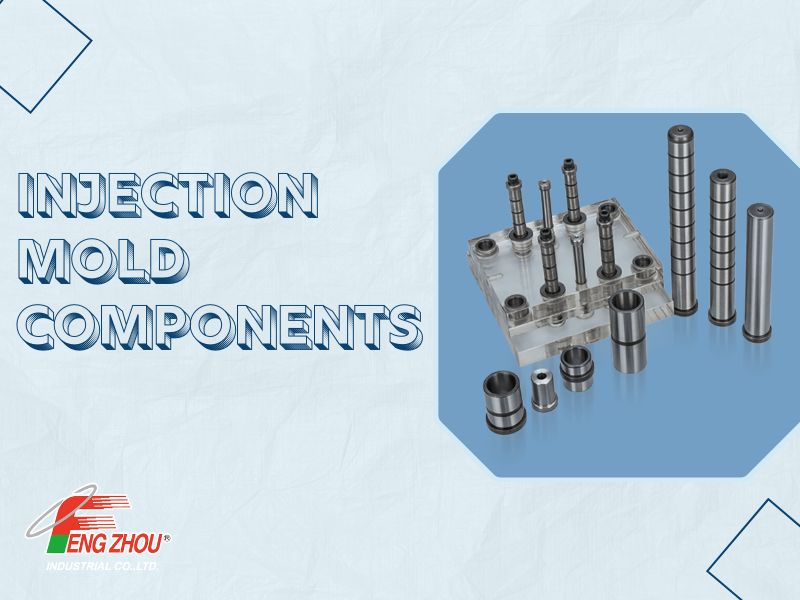

Understanding Plastic Mold Components

Plastic mold components are the building blocks of the plastic molding process. These components ensure that the mold functions correctly, producing high-quality plastic parts with precise dimensions and features. Here are some of the most essential plastic mold components:

-

Guide Pins and Guide Bushings

Guide pins and guide bushings are critical for aligning the mold halves accurately during the molding process. These components ensure that the mold closes correctly, which is vital for maintaining the dimensional accuracy of the molded parts.

Benefits:

- Accurate Alignment: Prevents misalignment, reducing the risk of defects.

- Durability: Made from hardened steel or other durable materials to withstand repetitive use.

- Consistency: Ensures consistent production quality across multiple cycles.

-

Ejector Pins

Ejector pins are used to eject the finished part from the mold cavity after the molding process is complete. These pins must be precisely machined to avoid damaging the molded part during ejection.

Benefits:

- Smooth Ejection: Prevents damage to the molded parts during the ejection process.

- Precision: Available in various sizes and shapes to suit different mold designs.

- High Durability: Constructed from materials that resist wear and deformation.

-

Return Pins

Return pins help in returning the mold to its original position after the part is ejected. They play a crucial role in maintaining the cycle time of the molding process, ensuring efficient and smooth operation.

Benefits:

- Cycle Efficiency: Enhances the efficiency of the molding process by ensuring quick return of the mold.

- Stability: Provides stability and prevents misalignment during the return phase.

- Reliability: Made from robust materials to ensure consistent performance.

-

Core Pins

Core pins are used to form internal features within the molded part. They must be precisely machined to maintain the integrity and accuracy of the mold.

Benefits:

- Internal Features: Creates precise internal geometries in molded parts.

- Versatility: Can be adjusted to meet specific design requirements.

- High Precision: Ensures dimensional accuracy of internal features.

-

Sprue Bushings

Sprue bushings are responsible for directing the molten plastic material from the injection nozzle into the mold cavity. They must be able to withstand high temperatures and pressures during the injection process.

Benefits:

- Efficient Flow: Ensures smooth and consistent flow of molten plastic into the mold.

- Heat Resistance: Made from materials that can endure high temperatures.

- Precision Fit: Reduces material waste and enhances mold performance.

The Importance of Material Selection

The performance and durability of plastic mold components are heavily influenced by the materials used in their construction. Common materials include:

- Hardened Steel: Offers excellent wear resistance and durability, ideal for high-pressure applications.

- Stainless Steel: Provides corrosion resistance, suitable for environments with exposure to moisture.

- Bronze: Known for its low friction properties, enhancing the smooth operation of moving parts.

Choosing the right material ensures that the mold components can withstand the stresses of the molding process and maintain their precision over time.

Enhancing Precision Manufacturing with Quality Components

High-quality plastic mold components are integral to the success of precision manufacturing. They ensure that every part produced meets strict quality standards, with minimal defects and maximum efficiency. At FENG ZHOU INDUSTRIAL CO., LTD., our commitment to excellence in manufacturing and material selection guarantees that our components will deliver superior performance and durability.

Conclusion

Plastic mold components are the foundation of any successful plastic molding operation. By ensuring that these components are of the highest quality, manufacturers can achieve greater precision, efficiency, and product quality. Whether you need guide pins, ejector pins, core pins, or sprue bushings, FENG ZHOU INDUSTRIAL CO., LTD. offers comprehensive solutions designed to meet your specific manufacturing needs.

To learn more about how our plastic mold components can enhance your production processes, explore our product offerings or contact us directly. We are dedicated to providing solutions that not only meet but exceed your expectations in precision engineering.

LASTEST TECHNOLOGY