Essential Mold Components for Precision Manufacturing

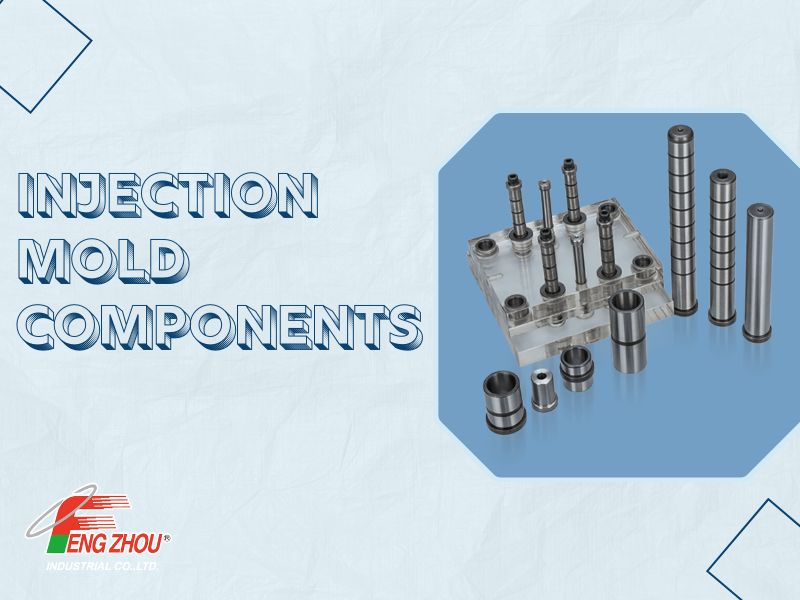

In the world of precision manufacturing, the quality and performance of mold components are critical for ensuring the efficiency and accuracy of production processes. At FENG ZHOU INDUSTRIAL CO., LTD., we specialize in producing and exporting high-quality plastic mold components such as guide pins, guide bushings, return pins, support pins, ejector guide pins, pull rods, and washers. This article will explore the essential mold components and their importance in achieving precision manufacturing.

Key Takeaways

- Precision Components: High-quality mold components are crucial for maintaining the accuracy and efficiency of manufacturing processes.

- Durable Materials: Selecting the right materials for mold components ensures their longevity and reliability.

- Innovative Design: Advanced design features in mold components contribute to improved performance and reduced downtime.

- Comprehensive Solutions: A range of essential mold components is necessary for a complete and effective manufacturing system.

Essential Mold Components

1. Guide Bushings

Guide bushings are vital for aligning mold halves and ensuring precise movement during the molding process. They are typically made from hardened steel or other durable materials to withstand the demands of high-pressure operations.

Benefits:

- Accurate Alignment: Ensures mold halves are perfectly aligned, reducing defects.

- Wear Resistance: Made from materials that resist wear and extend the lifespan of the mold.

- Smooth Operation: Minimizes friction, enhancing the efficiency of the molding process.

2. Guide Pins

Guide pins work in conjunction with guide bushings to provide accurate alignment and support for mold halves. These components are essential for maintaining the integrity of the mold and ensuring high-quality output.

Benefits:

- Precision: Provides exact alignment of mold components.

- Durability: Constructed from high-strength materials to resist bending and wear.

- Consistency: Ensures consistent performance and reduces the need for frequent adjustments.

3. Ejector Pins

Ejector pins are used to eject the finished part from the mold cavity after the molding process is complete. These pins must be highly durable and precisely machined to avoid damaging the molded part.

Benefits:

- Precision Ejection: Ensures smooth and damage-free removal of the part.

- High Durability: Made from materials like hardened steel to withstand repetitive use.

- Customizable: Available in various sizes and shapes to fit different mold designs.

4. Support Pins

Support pins provide additional stability and support to the mold during the injection process. They are essential for maintaining the structural integrity of the mold and preventing deformation.

Benefits:

- Enhanced Stability: Provides additional support to maintain mold integrity.

- Durability: Constructed from materials that can withstand high pressures.

- Precision: Ensures accurate alignment and reduces the risk of mold deformation.

The Importance of Material Selection

Selecting the right materials for mold components is crucial for ensuring their performance and longevity. Common materials include:

- Hardened Steel: Offers excellent wear resistance and durability, ideal for high-pressure applications.

- Stainless Steel: Provides corrosion resistance, suitable for environments exposed to moisture.

- Bronze: Known for its low friction properties, enhancing the smooth operation of moving parts.

Innovative Design Features

Modern mold components often incorporate advanced design features to enhance their performance and reduce maintenance requirements. These features include:

- Self-Lubricating Bushings: Reduce the need for external lubrication, minimizing maintenance.

- Heat-Treated Surfaces: Increase hardness and wear resistance, extending the component’s lifespan.

- Precision Machining: Ensures tight tolerances and accurate fit, improving the overall efficiency of the mold.

Comprehensive Solutions for Precision Manufacturing

We offer a comprehensive range of essential mold components designed to meet the needs of precision manufacturing. Our commitment to quality and innovation ensures that our components deliver superior performance and reliability.

Why Choose Us?

- Expertise: Extensive experience in the precision manufacturing industry.

- Quality Assurance: Rigorous testing and quality control to ensure the highest standards.

- Customized Solutions: Tailored components to meet specific customer requirements.

- Support: Dedicated customer service to assist with all your manufacturing needs.

Conclusion

Essential mold components play a critical role in the success of precision manufacturing processes. By choosing high-quality components from us, manufacturers can achieve superior accuracy, efficiency, and product quality. Our comprehensive solutions are designed to meet your precise requirements, ensuring that your production processes are optimized for the best performance.

To explore our product range or to contact us directly for more information on how we can support your precision manufacturing needs, we are committed to delivering solutions that not only meet but exceed your expectations in precision engineering.

LASTEST TECHNOLOGY