What Are the Key Components of an Injection Mold?

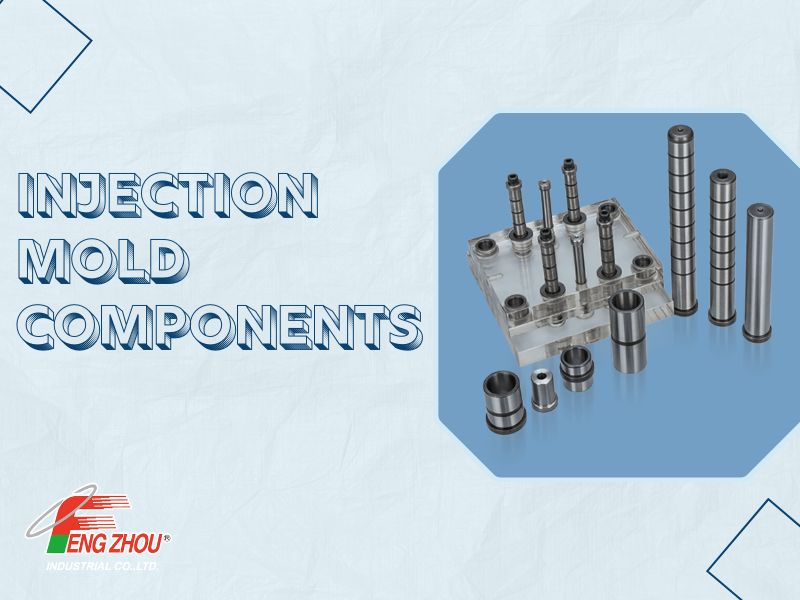

Injection molding is pivotal in manufacturing, shaping the production landscape across various sectors with its precision and versatility. At Fengzhou Precision Mold Limited, we take pride in our contribution to this field, providing key components of injection molds tailored to a broad spectrum of industry needs.

- Mold Base and Plates: At the core of injection molding is the mold base, which includes several crucial plates such as the A plate (cavity side), B plate (core side), and support plates. These plates not only support and align the mold but also bear the brunt of the injection pressure. In automotive manufacturing, for example, the robustness of these plates is critical to producing parts with the structural integrity required for safety and performance.

- Mold Cavity and Core: The cavity and core are where the product takes shape, with the cavity forming the exterior and the core defining the interior of the part. Precision here is essential, especially in the medical sector where mold components must create parts that comply with strict regulatory standards.

- Ejection System: The ejection system is responsible for safely removing the solidified part from the mold without causing any damage. This component is particularly vital in the consumer electronics industry where the aesthetic quality of a part, such as a sleek smartphone case, is as critical as its functionality.

- Cooling System: The cooling system is designed to maintain the mold at the correct temperature, ensuring that each part has a consistent quality and structural integrity. This system's design is especially important in the aerospace industry, where materials must perform under extreme conditions.

- Runner System and Gates: The runner system is the network of channels that directs the molten plastic into the cavities. Along with the gates, which control the flow into each cavity, they are finely tuned to prevent defects and ensure high-quality production. In the packaging industry, these components are key to achieving the precise, airtight seals necessary for food safety.

Applications Across Industries Fengzhou's injection mold components serve a multitude of industries:

- Automotive: We engineer plates, cavities, and cores that withstand intense production demands and meet stringent safety standards.

- Medical: Our molds produce sterile, high-precision devices and casings, following the industry's rigorous protocols.

- Consumer Electronics: We ensure the high-quality finish and detail necessary for consumer satisfaction in electronic devices.

- Packaging: We craft molds that provide the durability and protection essential for packaging materials.

- Aerospace: Our components are designed for resilience, contributing to the safety and efficiency of aerospace parts.

- Construction: We supply molds for robust construction materials, plumbing fixtures, and HVAC systems, which require durability and precision.

Conclusion

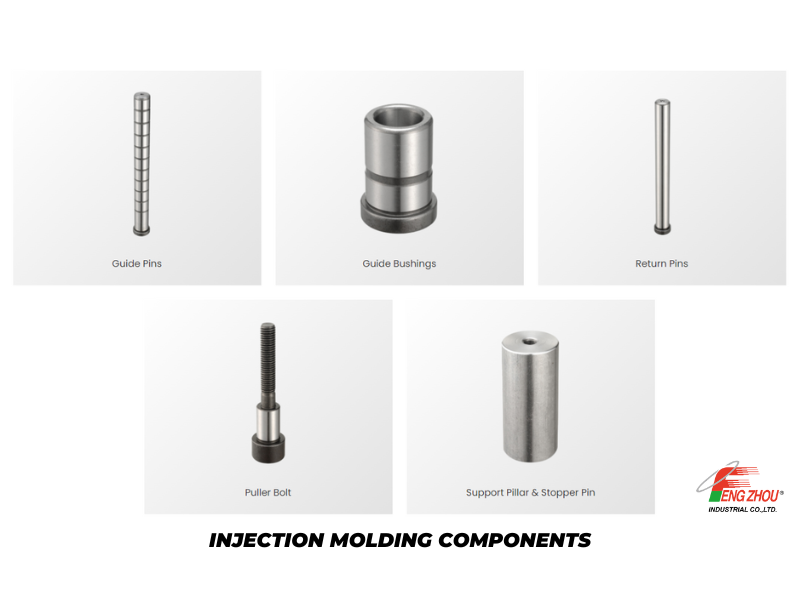

In the dynamic and exacting world of injection molding, Fengzhou Precision Mold Limited stands as a beacon of quality and innovation. Specializing in essential mold components such as guide pins, guide bushings, return pins, puller bolts, and support pillars & stopper pins, we play a pivotal role in enhancing the efficiency and reliability of the molding process. Our commitment to precision engineering and customer satisfaction makes us a trusted partner in various industries. Each product we offer embodies our dedication to excellence, contributing significantly to the success of our clients' manufacturing operations.

We invite you to explore the precision and craftsmanship that define Fengzhou Precision Mold Limited. Visit our website to learn more about our diverse range of mold components and how we can support your manufacturing goals. Together, let's drive innovation and quality in the world of injection molding.

LASTEST TECHNOLOGY