The Manufacturing Process of Guide Bushings: From Design to Production

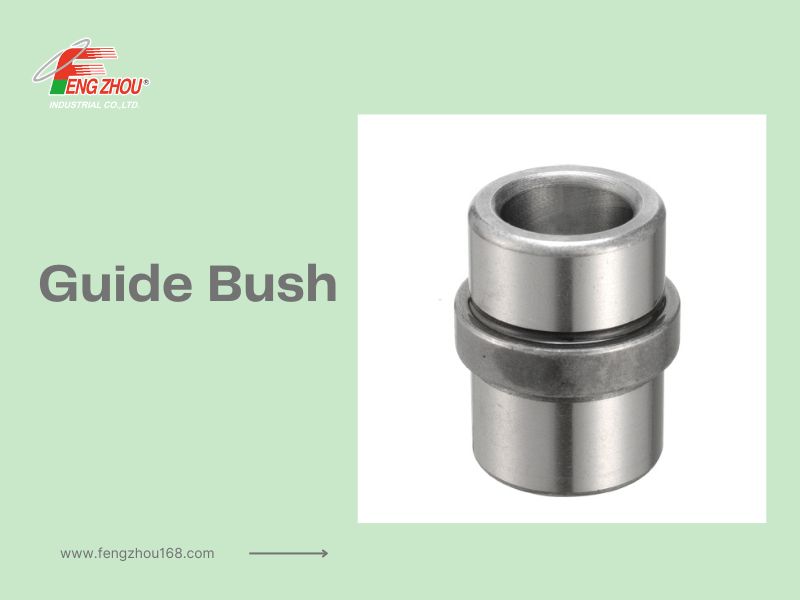

In injection molding, a guide bushing is a key part. It guides the mold halves or components inside the mold, ensuring they move correctly. The bushing is put in the stationary half of the mold and helps the other half move accurately.

At FENG ZHOU INDUSTRIAL CO., LTD., we specialize in producing high-quality guide bushings that enhance the efficiency and precision of injection molding operations.

Key Takeaways

- Critical Role: Guide bushings play a critical role in maintaining alignment and efficiency in injection molding processes.

- Durable Materials: They are typically made of hardened steel or other wear-resistant materials to withstand the demands of the molding operation.

- Essential Design: Careful design, precision manufacturing, and quality control are essential to ensuring guide bushings perform their intended function effectively.

- Production Optimization: By using high-quality guide bushings, manufacturers can achieve consistent part quality, optimize production efficiency, and maximize the overall performance of their injection molding operations.

- Material Selection: The selection of the right materials and manufacturing processes for guide bushings is crucial to their performance and longevity in the injection molding environment.

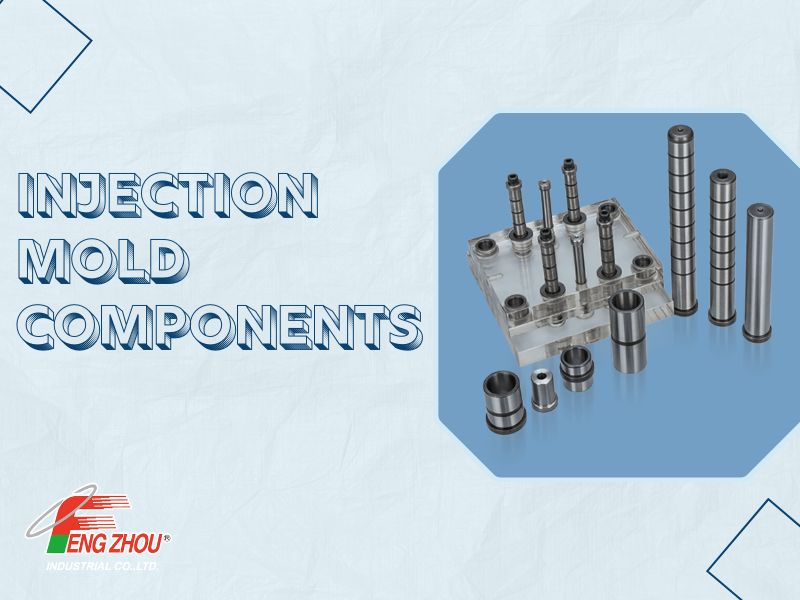

What are Guide Bushings?

In the world of injection molding, guide bushings are key. They help keep the mold precise and efficient. These "guide pin bushings" or "guide sleeves" direct the movement of mold parts or the mold itself. Their job is to support and align the mold pieces, ensuring accurate operation and the production of high-quality plastic parts.

Role in Injection Molding

Guide bushings guide the upper and lower molds into place accurately. They are vital in many injection molding applications, and larger molds might also have guide plates. Even a micro die could have a guide tube, which is just as important as a guide sleeve.

Components and Materials

These bushings are usually made from durable materials like hardened steel. Other materials like D2 or M2 tool steels, stainless steel, or bronze are also used. The material choice depends on various factors, including the molding process and the conditions they'll face.

Material Selection and Properties

- Hardened Steel: Known for its high strength and wear resistance, making it ideal for high-volume production.

- D2 and M2 Tool Steels: Offer excellent wear resistance and toughness, suitable for high-stress applications.

- Stainless Steel: Provides good corrosion resistance, beneficial in environments where moisture is a concern.

- Bronze: Used for its excellent anti-friction properties, ensuring smooth operation.

Design Considerations

Designing guide bushings for injection molding involves considering many factors, including the materials to be molded, the loads they will experience, and the environment. Using tough materials like hardened steel helps the bushings last longer. Good fitting and a smooth surface are also key for keeping molds aligned and moving correctly.

Key Design Factors

- Load Bearing: The bushing must support the load without deforming.

- Alignment Accuracy: Ensuring precise alignment to maintain the integrity of the mold.

- Wear Resistance: Materials should be chosen to withstand the friction and pressure of the molding process.

- Thermal Stability: Ability to maintain performance under varying temperatures.

Precision Manufacturing

To make guide bushings, they are cut, drilled, and ground with precision. This ensures they are the right shape and have a smooth surface. Sometimes, the outside is polished or finely ground for an even smoother finish, which helps molds move efficiently during injection molding.

Manufacturing Steps

- Material Selection: Choosing the right material based on application requirements.

- Cutting and Shaping: Using CNC machines to cut the material to precise dimensions.

- Drilling and Boring: Creating the necessary holes with high accuracy.

- Grinding: Smoothing the surface to ensure minimal friction.

- Heat Treatment: Hardening the material to improve wear resistance.

- Finishing: Polishing and fine grinding to achieve a smooth, high-quality finish.

Quality Control

At FENG ZHOU INDUSTRIAL CO., LTD., we subject our guide bushings to rigorous quality control measures. They undergo tests to check their dimensions, surface finish, and hardness. Our commitment to quality ensures that our guide bushings perform reliably, making the molding process more dependable.

Quality Assurance Processes

- Dimensional Inspection: Ensuring all dimensions meet the design specifications.

- Surface Finish Testing: Checking for smoothness and uniformity.

- Hardness Testing: Verifying the hardness level to ensure durability.

- Performance Testing: Simulating operating conditions to test functionality.

Conclusion

In the precision molding field, guide bushings are essential components. They help maintain the injection molding process's efficiency and accuracy. With high-quality guide bushings from FENG ZHOU INDUSTRIAL CO., LTD., manufacturers can achieve better part quality and faster production, improving overall performance.

The making of guide bushings requires careful planning, including selecting the right materials, ensuring accurate dimensions, and achieving a smooth finish. This helps in maintaining proper movement and extending the life of the parts.

As the molding industry evolves, guide bushings from FENG ZHOU INDUSTRIAL CO., LTD. will continue to be vital for keeping machines accurate and efficient. By choosing our top-quality guide bushings, your molds can produce superior products, advancing your position in the precision molding world.

For more information about our products and how we can support your needs, please contact us directly. We are committed to providing you with the best solutions to meet your precision engineering requirements.

LASTEST TECHNOLOGY