Guide Bushings for Different Industries: Applications and Benefits

In the complex field of precision engineering, one small part plays a crucial role in machine efficiency: the guide bushing. This component is essential for ensuring machines work smoothly and last longer across various applications. At FENG ZHOU INDUSTRIAL CO., LTD., we specialize in manufacturing high-quality guide bushings that meet the rigorous demands of various industries.

But what makes guide bushings so special? Why are they important, and how do they enhance machine performance? Let's delve into the world of guide bushings, uncovering their significance and their impact across different industries.

Key Takeaways

- Precision Engineering: Guide bushings are engineered components that provide alignment and support for moving parts in machinery.

- Durability: Made from materials like hardened steel or alloys, guide bushings offer exceptional wear resistance and extended service life.

- Operational Efficiency: With tight tolerances, guide bushings facilitate smooth and controlled movements, minimizing friction and enhancing overall efficiency.

- Versatile Applications: Guide bushings are used in various industries, including automotive, aerospace, and precision machining, where precision is paramount.

- Optimal Performance: These components are crucial for ensuring the optimal performance and longevity of the machinery they support.

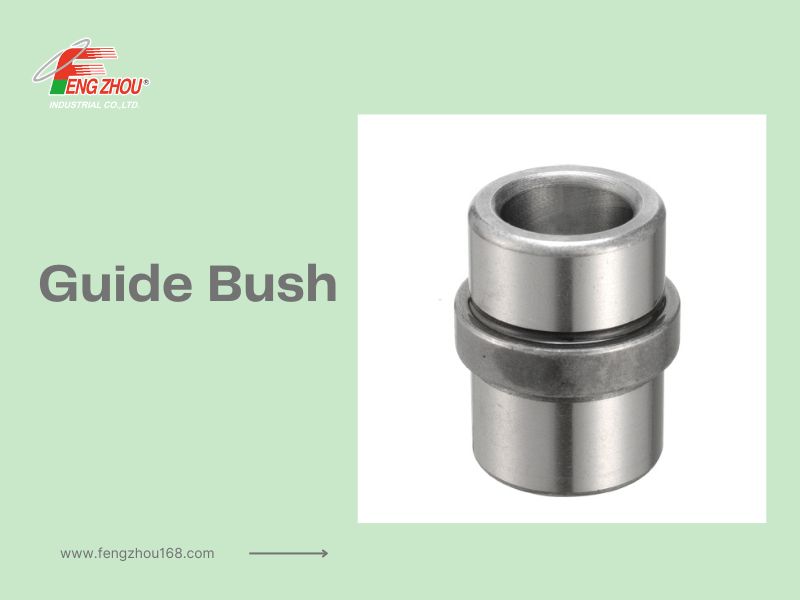

The Essence of Precision: Guide Bushings Explained

Guide bushings ensure that parts move together with high precision, made using exact measurements for accuracy.

Engineered for Accuracy

Guide bushings are all about precision. Their surfaces and specifications are meticulously crafted for accurate performance in demanding applications.

Durable and Wear-Resistant Materials

Constructed from tough materials like hardened steel, guide bushings reduce wear, extending their lifespan and enhancing performance.

Facilitating Smooth and Controlled Movements

Guide bushings help machinery operate smoothly, minimizing friction, improving efficiency, and preventing premature wear and tear.

Diverse Applications: Where Guide Bushings Shine

Guide bushings are used in many industries, demonstrating their flexibility and critical importance. They ensure operations are precise, reliable, and efficient.

Automotive Industry

In the automotive industry, guide bushings are essential for aligning parts like steering and suspensions. This precision results in smoother vehicle operation, enhancing reliability and driver satisfaction.

Aerospace Industry

In aerospace, guide bushings ensure the precise alignment of critical moving parts. Whether for an aircraft's landing gear or a satellite's stabilization, their high performance is vital for safety and precision.

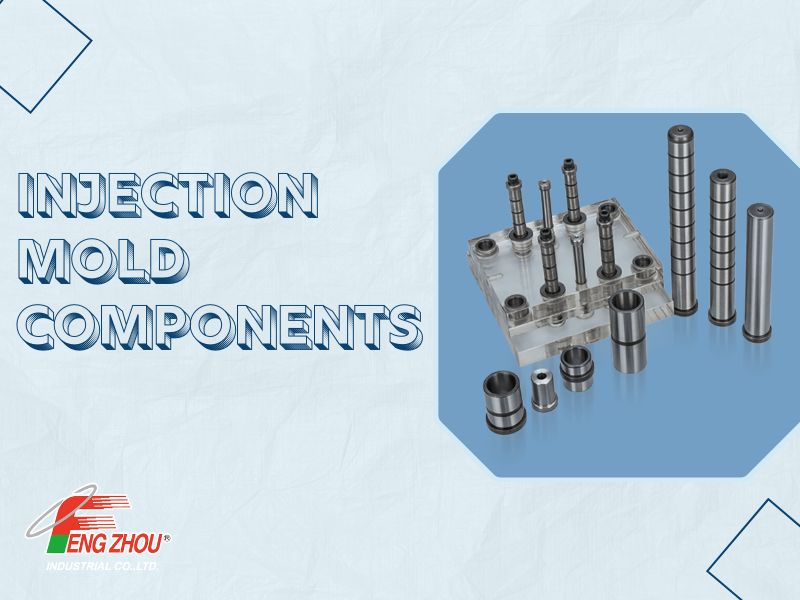

Precision Machining and Tooling

In precision machining and tooling, guide bushings align parts like drill bits and cutting tools accurately. This accuracy is crucial for manufacturing high-quality components and enhancing machine efficiency.

Guide Bushings: Enhancing Machinery Performance

Guide bushings are key to setting parts in motion correctly in machines. They ensure parts move as they should, reducing wear and tear. With their sharp precision and sturdy construction, they enhance machinery performance and reliability.

Alignment and Support for Moving Parts

The precise fit of our guide bushings keeps components aligned, ensuring smooth operation and preventing early breakdowns. This alignment is essential for steady, trouble-free production.

Minimizing Friction and Enhancing Efficiency

Designed to combat friction, our guide bushings use high-quality materials and advanced engineering techniques. Less friction means smoother operation, lower costs, and higher efficiency, benefiting both the bottom line and the environment.

Extended Service Life and Dependability

Built with wear-resistant materials, our guide bushings are designed to last longer and perform better, reducing downtime and maintenance costs. This ensures reliable machine operation and cost savings.

Conclusion

Guide bushings are critical components that ensure machines operate with precision and longevity. They are highly accurate, durable, and facilitate smooth movement, which is essential for optimal machinery performance.

At FENG ZHOU INDUSTRIAL CO., LTD., we take pride in producing top-quality guide bushings that enhance productivity, reduce maintenance costs, and improve the utilization of machinery. In industries such as automotive, aerospace, and precision machining, our guide bushings are indispensable. They help make production faster, cut down on repair costs, and optimize machine use, making them invaluable in achieving high-quality outcomes.

As engineering continues to advance, guide bushings will become even more vital. Their precision and durability enable better machine performance, saving time and money, and driving progress and success across various fields.

For more information about our products and how we can support your needs, please contact us directly. We are committed to providing you with the best solutions to meet your precision engineering requirements.

FAQ

What are guide bushings and what are their key features?

Guide bushings align and support moving parts in various industries. Made with precision and durable materials like steel or alloys, they ensure smooth movement with minimal friction, enhancing overall machine performance.

How do guide bushings contribute to the performance and longevity of machinery?

Guide bushings are engineered with tight tolerances to maintain precise movement, crucial in high-precision applications. Their robust construction reduces wear and tear, cutting down on maintenance and extending machinery life.

In what industries are guide bushings commonly used?

Guide bushings are essential in automotive, aerospace, and precision machining industries. They ensure parts like steering and braking systems in vehicles, critical components in aircraft, and precision tools in manufacturing operate accurately and efficiently.

How do guide bushings contribute to the efficiency and productivity of industrial equipment?

Their precise design allows for smooth, low-friction movement, crucial for optimal machine performance and longevity. Their durable construction reduces maintenance needs, keeping machines operational and productive.

What are the key factors that make guide bushings an essential component in industrial applications?

Guide bushings are vital for ensuring parts operate correctly without premature wear or failure. Their precision, durability, and ability to facilitate smooth movement make them indispensable in automotive, aerospace, and precision machining applications, ensuring reliable and accurate machine operation.

LASTEST TECHNOLOGY