08 MAY2024

SUJ2 Guide Bushing and Copper Guide Bushing

When selecting materials for guide bushings, SUJ2 and copper are popular choices, each offering distinct advantages and suited to different applications.

SUJ2 Material

- Advantages: SUJ2 is a high-carbon chromium bearing steel known for its excellent hardness and wear resistance. It performs well under high-load and high-speed conditions.

- Disadvantages: SUJ2 can be less effective in corrosive environments unless properly coated or treated.

- Applications: Ideal for applications requiring durability and resistance to deformation, such as in automotive and industrial machinery.

Copper Material

- Advantages: Copper bushings excel in thermal conductivity and natural resistance to corrosion, making them suitable for environments with variable temperatures and chemicals.

- Disadvantages: Softer than SUJ2, copper wears out more quickly under heavy loads and requires more frequent replacement.

- Applications: Best for electrical applications and machinery where overheating is a concern, and in sectors like aerospace and marine engineering.

Material Comparison

- Wear Resistance: SUJ2 outperforms copper.

- Corrosion Resistance: Copper offers better corrosion resistance.

- Cost-Effectiveness: Depending on the application, each material may be more cost-effective; copper generally costs less but may incur higher maintenance costs.

How to Choose the Right Material

- Assess Application Requirements: Consider the mechanical loads, speeds, and environmental conditions of the application.

- Evaluate Material Properties: Look at hardness, wear resistance, corrosion resistance, and thermal properties.

- Consider Longevity and Maintenance Needs: Factor in the lifespan and maintenance frequency required by the material.

At Fengzhou Precision Mold Limited, our expertise in SUJ2 steel for guide bushings ensures that our products meet the highest standards of quality and performance, providing reliable and efficient solutions for complex manufacturing challenges. For more information on our guide bushings and how to select the best material for your needs, visit our website.

LASTEST TECHNOLOGY

18 DEC,2024

Guide Pin: The Key to Precision and Efficiency in Manufacturing

18 NOV,2024

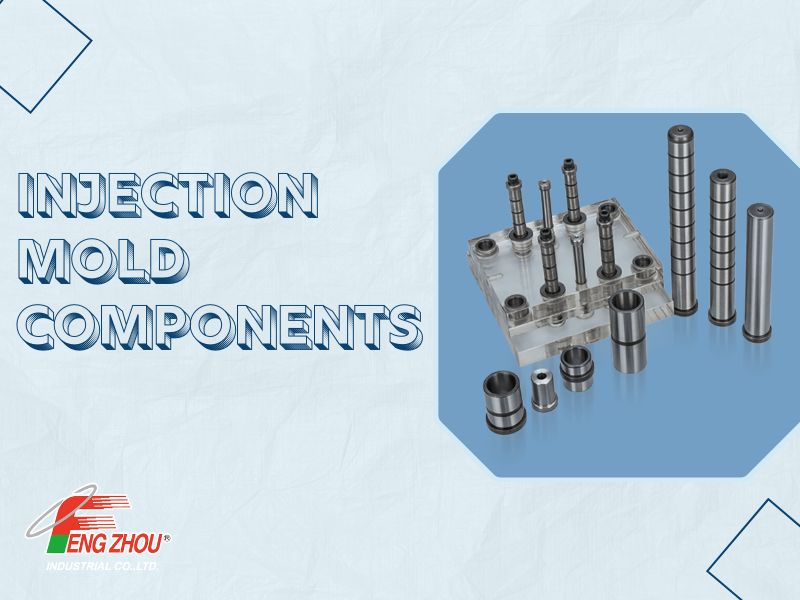

How Injection Mold Components Enhance Efficiency in Manufacturing

23 OCT,2024

5 Key Benefits of Using a Guide Bush in Precision Manufacturing

23 SEP,2024

Return Pin: Essential Component for Mold Efficiency

26 AUG,2024

Plastic Mold Components: Essential Parts Explained